Rütten Vibromixer™ R2-R3

Vibromixer R2/R3 monuted on a Rütten sterile vessel.

Cross section showing the mixing plate of the vibromixer R2/R3.

Cross section showing the mixing plate of the vibromixer R2/R3.

Advanced vibrating agitator for high value liquids—30 to 250 litres (8 to 65 US gal)—250 to 1000 litres (65 to 265 US gal).

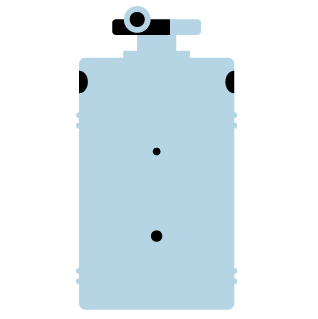

Sterile Storage System (SSS)

Sterile Storage System (SSS)

Application :

Blending Dispersion Homogenisation Suspension Heat transfer Emulsification of immiscible liquids Shear induced particle size definition

Operative range :

Anaerobic vaccines : tetanus, pertussis, diphtheria Insuline Blood plasma

Sterile Storage System (SSS)

Sterile Storage System (SSS)Application :

Blending Dispersion Homogenisation Suspension Heat transfer Emulsification of immiscible liquids Shear induced particle size definition

Operative range :

Anaerobic vaccines : tetanus, pertussis, diphtheria Insuline Blood plasma

The vibrating shaft is perfectly sealed with a simple teflon/silicon membrane. There are no rotating parts or mechanical seals in the system that could generate any particles. As all parts with product contact are directly exposed to the product, the system is easy to clean.

| Units | Vibromixer R2 | Vibromixer R2 | |

| Mixing capacity | l US gal | 30 to 250 (8 to 66) | 250 to 1000 (66 to 265) |

| Stirrer plate diameter | mm in | 145 (5.71) | 195 (7.68) |

| Vibration amplitude 50 Hz (230 V 1 Ph, 2A) | mm (in) | 0 to 2.5 (0 to 0.10) | 0 to 2.5 (0 to 0.10) |

| Vibration amplitude 60 Hz (230 V 1 Ph, 2A) | mm (in) | 0 to 2.0 (0 to 0.08) | 0 to 2.0 (0 to 0.08) |

| Weight | kg lbs | 20 (44) | 36 (79) |

| Operating pressure | bar | -1 to 2 | |

| Material stirrer | AISI 316L, ground Ra < 0.3, electropolished Special alloys upon request |

||

| Material sterile sealing unit | Reinforced Silicone + PTFE | ||

| Material motor housing | AISI 304 in hygienic design | ||

| Vibromixer R2/R3 | |||

| Controller types | VC-030 | VPC-090 | VPC-070/080 |

| Mixing direction | Upflow | Downflow | ||

| Material stirrer | Special alloys available upon request | ||

| Stirrer shaft length | Application specific | ||

| Process connection | TC connectors for filling vessels | DN 150 or 200 head plate | Flanges for tanks > 500 L | ||

| Description | Thyristor amplitude controller | Frequency converter | Full PI-control system with frequency converter and high precision amplitude sensor |

| Power supply | 110-230 V, 6.0 A | 230 VAC / Amps | 230 VAC / Amps |

| Input frequency | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz |

| Output frequency | 50 / 60 Hz | 33-66 Hz | 33-66 Hz |

| Broken sensor cable detection | stop | ||

| Amplitude selection | stop | stop | stop |

| Amplitude measurement and tuning | stop | ||

| Frequency tuning | stop | stop | |

| Alarm output | stop | ||

| Motor power output | stop | ||

| Material cabinet | Aluminium case | Stainless steel case | Stainless steel case |

| Dimensions [mm] | 120 × 90 × 140 | ... | 330 × 165 × 275 |

| User interface | Potentiometer | LCD Display and Potentiometer | Full graphic display with keyboard, manual start / stop key |

| Signals | 4…20 mA and Profibus start / stop / alarm |

||